EURO BUSINESS SRL

© EURO BUSINESS SRL

Made by Mars

Aluminium sheet

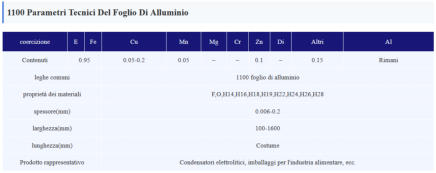

1100 Introduction to Aluminum Foil

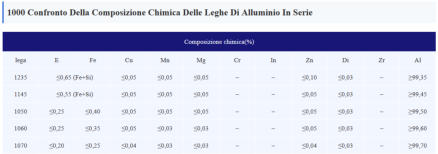

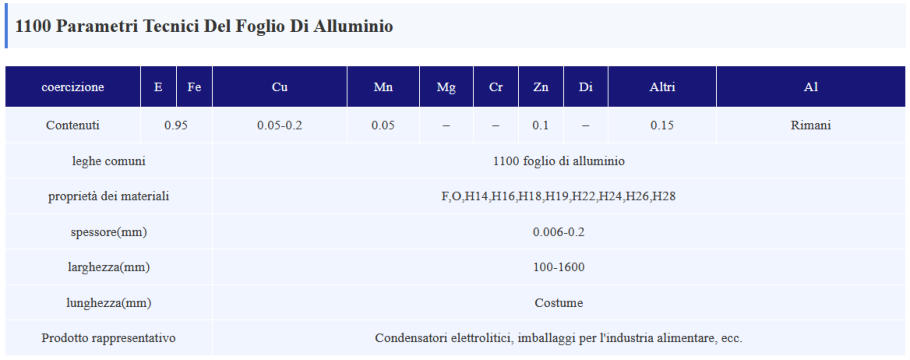

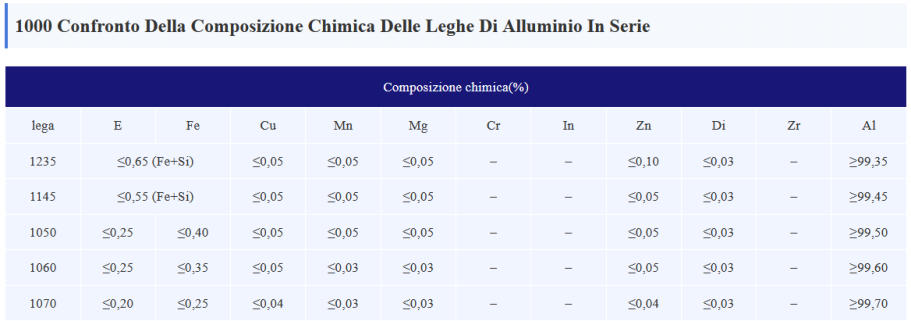

The aluminum content of aluminum foil is 99% or more and contains traces of silicon and iron. These impurities help improve the processing performance of the material but do not affect its basic properties... 1100 Aluminum foil is formable, corrosion resistance, Excellent thermal conductivity and specific strength. This is a heat exchanger in the refrigeration industry, Storage containers in the chemical and food industry, Widely used in capacitor shell materials in the electronics industry. 1100 aluminum foil, 1050 aluminum foil, 1060 aluminum foil each 1000 Belongs to the aluminum foil series. The aluminum content is 99% This is the above, but there is not much difference in performance..

1100 Application Areas of Aluminum foil

Packaging industry: moisture-proof, Food

grade with excellent light blocking properties, medicinal, It is widely used as

packaging material for cosmetics, etc., aluminum paper, It is also used in the

production of plastic wraps, etc. ·construction industry: Used as materials for

thermal and acoustic insulation or mixed with other roofing materials, Used to

make wall sandwich panels, etc. ·Air conditioning and ventilation systems: As you

can see from the information above 1100 The sheet of Aluminum is often used as a

surface layer for phenolic composite air ducts to provide protection and improve

structural strength. ·Electronic products : It is used to produce wave shielding

materials electromagnetic for electronic products by exploiting its excellent

conductivity properties and shielding.. decorations and crafts: With matte or glossy

surface finish 1100 Aluminum foil is a decorative material, Can be used in art

production, etc. To add beauty.. ·etc: light weight, Ease of processing, Automotive

parts using resistance to corrosion, heat exchanger parts, bottle cap, printing plate,

etc..

Environmental considerations

1100 Aluminum, including alloys, is highly recyclable and is a environmentally

friendly material of the environment..

Recycling aluminum requires much less energy than producing

new aluminum from raw materials, contributing to energy saving and reduction of

greenhouse gas emissions….

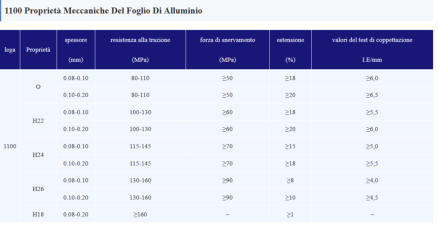

1100 Properties of Aluminum foil

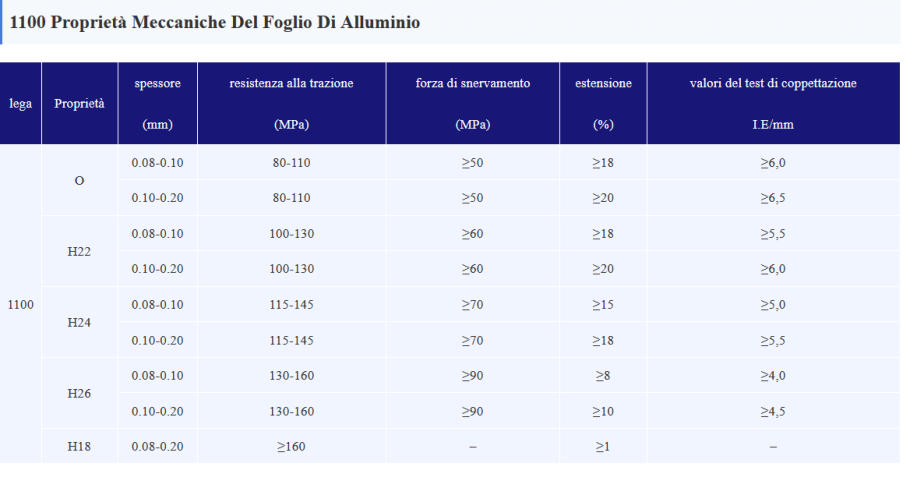

• ingredient: The main ingredient is aluminium, almost free of impurities, and may contain traces of silicon and iron. These impurities contribute to improving the processing performance of the material but do not affect its basic properties. • Strengthening without heat treatment: Hardness and strength cannot be improved by heat treatment., Mechanical properties mainly depend on cold work hardening.. • corrosion resistance: 1100 Because aluminum foil has high purity, it has excellent corrosion resistance and is suitable for use in a variety of environments., Especially suitable for use in chemically corrosive and corrosive atmospheric environments . • High electrical and thermal conductivity: This pure aluminum product has excellent electrical and thermal conductivity, making it suitable for applications requiring excellent electrical or thermal conductivity. • Low density and good plasticity: Less dense and more plastic than many other metals. Easy to machine and form, suitable for complex stamping and drawing operations.

EURO BUSINESS SRL

© EURO BUSINESS SRL

Made by Mars

Aluminium sheet

1100 Introduction to Aluminum Foil

The aluminum content of aluminum foil is 99% or more and contains traces of silicon and iron. These impurities help improve the processing performance of the material but do not affect its basic properties... 1100 Aluminum foil is formable, corrosion resistance, Excellent thermal conductivity and specific strength. This is a heat exchanger in the refrigeration industry, Storage containers in the chemical and food industry, Widely used in capacitor shell materials in the electronics industry. 1100 aluminum foil, 1050 aluminum foil, 1060 aluminum foil each 1000 Belongs to the aluminum foil series. The aluminum content is 99% This is the above, but there is not much difference in performance..